Mattress Roller Durability Testing Machine

Mattress Roller Durability Testing MachineMattress Durability Testing Machine has been manufactured to determine the durability of any type of mattress and boxspring unit, regardless of the materials of construction, by simulating long-term use conditions. There are several different methods used in......

Send Inquiry

Product Description

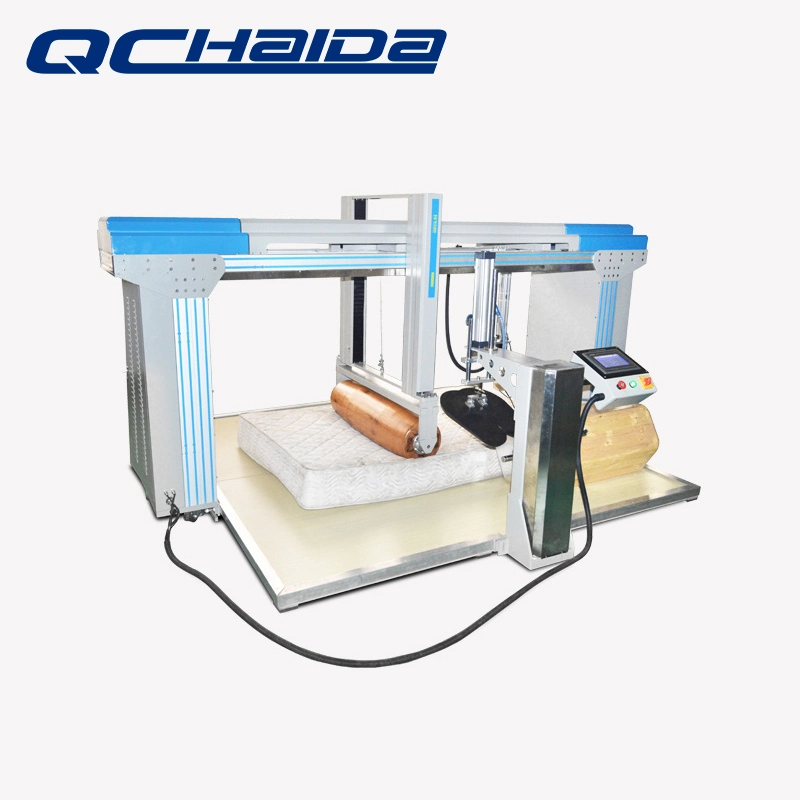

Mattress Roller Durability Testing Machine

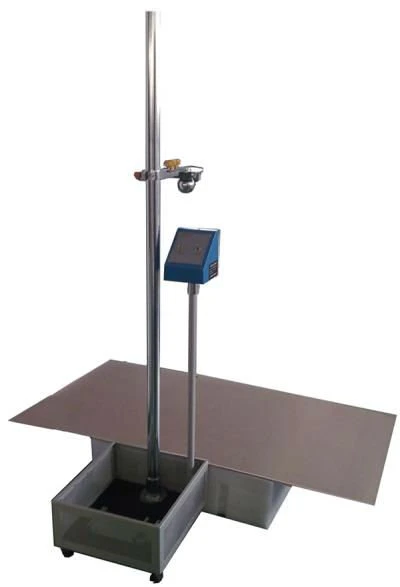

Mattress Durability Testing Machine has been manufactured to determine the durability of any type of mattress and boxspring unit, regardless of the materials of construction, by simulating long-term use conditions. There are several different methods used in the mattress industry for the evaluation of innerspring and box spring mattresses. The Cornell Type Tester is used to test for firmness and firmness retention, the Mattress Rollator is used to test for durability and the Bedding Impact Tester is used to assess the effect of impact.

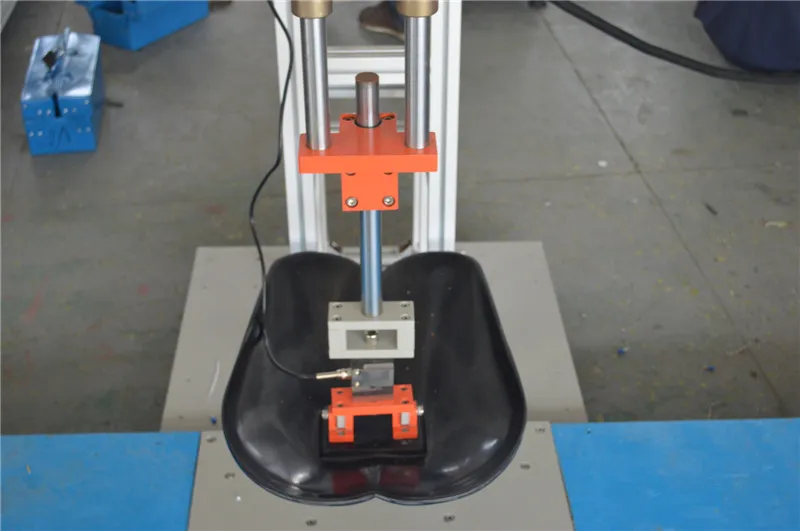

The Mattress Rollator consists of a weighted roller which moves width ways across a test mattress to simulate body movement. The length of stroke to which the Roller moves is very easily adjusted, by sliding the stroke adjustors left or right, to suit the relevant mattress under test. Unloading and loading of the Roller onto the test mattress is done easily via a motor driven lifting assembly.

Test standard: ASTM F1566, EN1957

Test purpose: Using a horizontal hexagonal wooden drum roll or cylinder (both ends of the diameter of 250 mm, the middle part of the 300 mm, rolling back and forth on the mattress, simulate human motion to assess the durability of the mattress.

Function and features:

Our company Introduction:

HAIDA INTERNATIONAL is a professional manufacturer of various kinds of testing equipments over 24 years. HAIDA products are widely used in paper products, packaging, ink printing, adhesive tapes, bags, footwear, leather products, environment, toys, baby products, hardware, electronic products, plastic products, rubber products and other industries, and applicable to all scientific research units, quality inspection institutions and academic fields.

Packaging & Shipping:

Simulation Animatronic Customer Triceratops are covered with air bubble film before put them into the wooden case, which not only has good shock absorption, impact resistance, heat sealing and also has the advantages of nontoxic, odorless, moisture corrosion, good transparency etc.

Mattress Durability Testing Machine has been manufactured to determine the durability of any type of mattress and boxspring unit, regardless of the materials of construction, by simulating long-term use conditions. There are several different methods used in the mattress industry for the evaluation of innerspring and box spring mattresses. The Cornell Type Tester is used to test for firmness and firmness retention, the Mattress Rollator is used to test for durability and the Bedding Impact Tester is used to assess the effect of impact.

The Mattress Rollator consists of a weighted roller which moves width ways across a test mattress to simulate body movement. The length of stroke to which the Roller moves is very easily adjusted, by sliding the stroke adjustors left or right, to suit the relevant mattress under test. Unloading and loading of the Roller onto the test mattress is done easily via a motor driven lifting assembly.

Test standard: ASTM F1566, EN1957

Test purpose: Using a horizontal hexagonal wooden drum roll or cylinder (both ends of the diameter of 250 mm, the middle part of the 300 mm, rolling back and forth on the mattress, simulate human motion to assess the durability of the mattress.

Function and features:

| Weight of hexagonal wood barrel | 109kg, Cylinder weight: 140kg |

| Maximum size of mattress | 2.3m× 2.5m |

| Machine size(L× W× H) | 2500mm× 2800mm× 2200mm |

| Power | 380V, 1.5kw |

| Motor | Taiwan's Teco Motor with reducer of Italy. |

| Speed adjustment | Taiwan's "ED Force" drive |

| Guide bearing | Import from Japan. |

| Rack | Aluminum body and steel |

| Control elements | Imported |

Our company Introduction:

HAIDA INTERNATIONAL is a professional manufacturer of various kinds of testing equipments over 24 years. HAIDA products are widely used in paper products, packaging, ink printing, adhesive tapes, bags, footwear, leather products, environment, toys, baby products, hardware, electronic products, plastic products, rubber products and other industries, and applicable to all scientific research units, quality inspection institutions and academic fields.

Packaging & Shipping:

Simulation Animatronic Customer Triceratops are covered with air bubble film before put them into the wooden case, which not only has good shock absorption, impact resistance, heat sealing and also has the advantages of nontoxic, odorless, moisture corrosion, good transparency etc.

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.